1. Scope * 1.1 This specification covers grades of nominal-wallthickness,austenitic alloy steel tubing for general corrosionresisting and low- or high-temperature service, having a specified minimum chromium content of less than 10.50 %. 1.2 The tubing sizes and thicknesses usually furnished to...

Online Inquiry

1. Scope

1.1 This specification covers grades of nominal-wallthickness,austenitic alloy

steel tubing for general corrosionresisting and low- or high-temperature

service, having a specified minimum chromium content of less than 10.50

%.

1.2 The tubing sizes and thicknesses usually furnished to this

specification are 1⁄4 in. (6.4 mm) in inside diameter and larger and 0.020

in. (0.51 mm) in nominal wall-thickness and heavier.

1.3 Mechanical property requirements do not apply totubing smaller than 1⁄8 in.

(3.2 mm) in inside diameter or 0.015 in. (0.38 mm) in thickness.

1.4 Some steels covered by this specification, especially the high silicon

containing steels, because of their particular alloy content and

specialized properties, may require special care in their fabrication and

welding. Specific procedures are of fundamental importance, and it is

presupposed that all parameters will be in accordance with approved

methods capable of producing the desired properties in the finished

fabrication.

1.5 The values stated in either inch-pound units or SI units are to be

regarded separately as standard. The values stated in each system are not

exact equivalents; therefore, each system must be used independently of

the other. Combining values from the two systems may result in

nonconformance with the specification. Unless the order specifies the

applicabl“M” specification designation (SI units), the material shall

be furnished in inch-pound units.

2. Referenced Documents

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing of Steel

Products2

A 480/A 480M Specification for General Requirements for Flat-Rolled

Stainless and Heat-Resisting Steel Plate, Sheet, and Strip2

A 632 Specification for Seamless and Welded Austenitic Stainless Steel

Tubing (Small-Diameter) for General Service3

A 1016/A 1016M Specification for General Requirements for Ferritic Alloy

Steels, Austenitic and Stainless Steel Tubes3

2.2 ANSI Standard:

B 31.3 Chemical Plant and Petroleum Refinery Piping4

2.3 ASME Pressure Vessel Code: Section VIII Division 1, Pressure

Vessels5

3. Ordering Information

3.1 Orders for material under this specification should include the

following, as required, to describe the desired material adequately:

3.1.1 Quantity (feet, metres, or number of lengths),

3.1.2 Name of material (seamless or welded tubes),

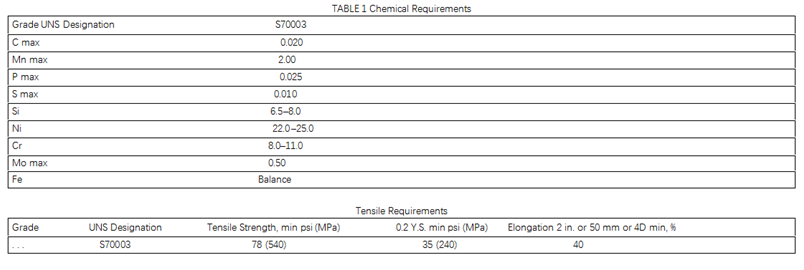

3.1.3 Grade (Table 1),

3.1.4 Size (outside diameter and nominal wall thickness),

3.1.5 Length (specific or random),

3.1.6 Test report required (see Section on Inspection of Specification A

1016/A 1016M),

3.1.7 Specification designation, and

3.1.8 Special requirements.

4. General Requirements

4.1 Material furnished under this specification shall conform to the

applicable requirements of the current edition of Specification A 1016/A

1016M, unless otherwise provided herein.

5. Manufacture

5.1 The tubes shall be made by the seamless or welded process.

5.2 At the manufacturer's option, tubing may be furnished either hot

finished or cold finished.

6. Heat Treatment

6.1 All material shall be furnished in the heat-treated condition. Except

as provided in 6.2, the heat-treatment procedure shall, consist of heating

the material to a minimum temperature of 1900°F (1040°C) and quenching in water

or rapidly cooling by other means.

6.2 Controlled structural or special service characteristics shall be

specified as a guide for the most suitable heat treatment. If the final

heat treatment is at a temperature under

1900°F and is so specified on the order, each tube shall be stenciled with

the final heat treatment temperature in degrees Fahrenheit after the

suffix “HT.”

6.3 S70003 shall be heat treated in the range 1920°F(1050°C) minimum to 2010°F

(1100°C) maximum followed by a water quench or rapid cooling by other

means.

9. Mechanical Tests Required

9.1 Flaring Test (Seamless Tubes)—One test shall be made on specimens from

one end of one tube from each lot (see Note1) of finished tubes.

NOTE 1—The term lot applies to all tubes prior to cutting to length of the

same nominal size and wall thickness which are produced from the same heat of

steel. When final heat treatment is in a batch-type furnace,

a heat-treatment lot shall include only those tubes of the same size and

from

the same heat that are heat treated in the same furnace charge. When

the final heat treatment is in a continuous furnace, the number of tubes

of the same size and from the same heat in a heat-treatment lot shall

be determined from the size of the tubes as prescribed in Table 2.

9.2 Flange Test (Welded Tubes)—One test shall be made on specimens from

one end of one tube from each lot (see Note 1) of finished tubes.

9.3 Hardness Test—Brinell or Rockwell hardness determination shall be made

on specimens from two tubes from each lot. The term lot applies to all

tubes prior to cutting, of the same nominal diameter and wall thickness

that are produced from the same heat of steel. When final heat treatment

is in a batch-type furnace, a lot shall include only those tubes of

the same size and the same heat which are heat treated in the

same furnace charge. When the final heat treatment is in a

continuous furnace, a lot shall include all tubes of the same size and

heat, heat treated in the same furnace at the same temperature,

time at heat, and furnace speed.

9.4 When more than one heat is involved, the flaring,flanging, and hardness

test requirements shall apply to each heat.

9.5 Reverse Flattening Test—For welded tubes, one reverse flattening test

shall be made on a specimen from each 1500 ft(460 m) of finished tubing. Coiled

tubing greater than 1500 ft(450 m) in length shall be sampled at both ends. A

coil must be continuous without any circumferential butt welds.

9.6 Hydrostatic or Nondestructive Electric Test—Each tube, seamless or

welded, shall be subjected to the Nondestructive Electric Test or the

Hydrostatic Test. Unless specified by the purchaser, either test may be used at

the option of the producer.

10. Hardness Requirements

10.1 S70003 shall have a maximum hardness of 220 HV or 95 HRB in the

annealed condition.

10.2 For tubing less than 0.065 in. (1.65 mm) in wall thickness, it is

permissible to use the Rockwell superficial hardness test or the Vickers

hardness test. The superficial hardness number for S70003 shall not exceed 79

on the 30 T scale or 91 on the 15 T scale.

10.3 No hardness test shall be required on tubes smaller than 1⁄4 in. (6.4

mm) in inside diameter or tubes having a wall thickness thinner than 0.020

in. (0.51 mm).

SUNRISE is well-known as one of the leading astm a953 austenitic

chromium nickel silicon alloy steel seamless and welded tubing manufacturers

and suppliers in China for its quality products and excellent service. We

warmly welcome you to buy the quality and durable steel products from our

factory.