1. Scope* 1.1 This specification covers several grades of carbon and alloy steel seamless mechanical tubing. The grades are listed in Tables 1-3. When welding is used for joining the weldable mechanical tube grades, the welding procedure shall be suitable for the grade, the condition of the...

Online Inquiry

1. Scope*

1.1 This specification covers several grades of carbon and alloy steel

seamless mechanical tubing. The grades are listed in Tables 1-3. When welding

is used for joining the weldable mechanical tube grades, the welding

procedure shall be suitable for the grade, the condition of the components, and

the intended service.

1.2 This specification covers both seamless hot-finished mechanical tubing

and seamless cold-finished mechanical tubing in sizes up to and including

12 3⁄4 in. (323.8 mm) outside diameter for round tubes with wall thicknesses as

required.

1.3 The tubes shall be furnished in the following shapes, as specified by

the purchaser: round, square, rectangular, and special sections.

1.4 Supplementary requirements of an optional nature are provided and when

desired shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the

standard. The values given in parentheses are for information only.

2. Referenced Documents

2.1 ASTM Standards: 2

A 370 Test Methods and Definitions for Mechanical Testing of Steel

Products

E 59 Practice for Sampling Steel and Iron for Determination of Chemical Composition3

2.2 Military Standards:

MIL-STD-129 Marking for Shipment and Storage4

MIL-STD-163 Steel Mill Products Preparation for Shipment and

Storage4

2.3 Federal Standard: Fed. Std. No. 123 Marking for Shipment (Civil

Agencies)4

3. Ordering Information

3.1 Orders for material under this specification should include the

following, as required, to describe the desired material adequately:

3.1.1 Quantity (feet, weight, or number of pieces),

3.1.2 Name of material (seamless carbon or alloy steel mechanical

tubing),

3.1.3 Form (round, square, rectangular or special shapes,Section 1),

3.1.4 Dimensions (round, outside diameters and wall thickness,Section 8; square

and rectangular, outside dimensions and wall thickness, Section 9; other,

specify),

3.1.5 Length (specific or random, mill lengths, see 8.5 and9.5),

3.1.6 Manufacture (hot finished or cold finished, 4.5 and4.6),

3.1.7 Grade (Section 5),

3.1.8 Condition (sizing method and thermal treatment, Section12),

3.1.9 Surface finish (special pickling, shot blasting, or ground outside

surface, if required),

3.1.10 Specification designation,

3.1.11 Individual supplementary requirements, if required,

3.1.12 End use, if known,

3.1.13 Packaging,

3.1.14 Product analysis and chemical analysis, if required (Section 6 and

Section 7),

3.1.15 Specific requirements, or exceptions to this specification,

3.1.16 Special marking (Section 15), and

3.1.17 Special packing (Section 16).

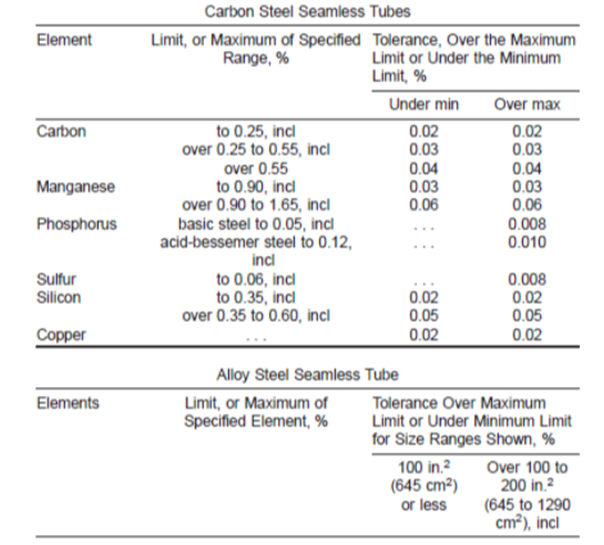

TABLE 3 Chemical Requirements for Alloy Steels

NOTE 1—The ranges and limits in this table apply to steel not exceeding 200

in.2(1290 cm2) in cross-sectional area.

NOTE 2—Small quantities of certain elements are present in alloy steels which

are not specified or required. These elements are considered as incidental and

may be present to the following maximum amounts: copper, 0.35 %; nickel, 0.25

%; chromium, 0.20 %; molybdenum, 0.10 %.

NOTE 3—The ranges and limits given in this table apply to heat analysis; except

as required by 6.1, product analyses are subject to the applicable additional

tolerances given in Table Number 5.

A

Grades shown in this table with prefix letter E generally are manufactured by

the basic-electric-furnace process. All others are normally manufactured by the

basic-open-hearth process but may be manufactured by the basic-electric-furnace

process with adjustments in phosphorus and sulfur.

B Grades shown in this table with the letter B, such as 50B40, can be expected

to have 0.0005 % minimum boron control.

C The phosphorus sulfur limitations for each process are as follows:

Basic electric furnace 0.025 max % Acid electric furnace 0.050 max %

Basic open hearth 0.040 max % Acid open hearth 0.050 max %

D Minimum and maximum sulfur content indicates resulfurized steels.

E The purchaser may specify the following maximum amounts: copper, 0.30 %;

aluminum, 0.050 %; and oxygen, 0.0015 %.

TABLE

5 Product Analysis Tolerances Over or Under Specified Range or Limit

NOTE 1—Individual determinations may vary from the specified heat limits or

ranges to the extent shown in this table except that any element in a heat may

not vary both above and below a specified range.

NOTE 2—In all types of steel, because of the degree to which phosphorus and

sulfur segregate, product analysis for these elements is not technologically

appropriate for rephosphorized or resulfurized steels unless misapplication is

clearly indicated.

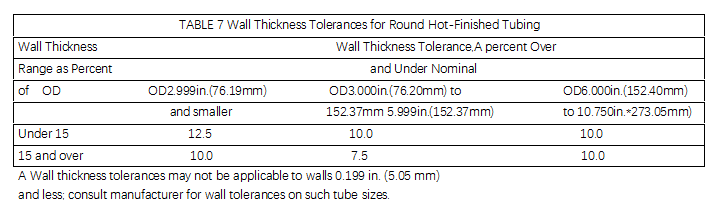

A Diameter tolerances are not applicable to normalized and tempered or quenched and tempered conditions.

B

The common range of sizes of hot finished tubes is 11⁄2 in. (38.1 mm) to 103⁄4

in. (273.0 mm) outside diameter with wall thickness at least 3 % or more of

outside diameter, but not less than 0.095 in. (2.41 mm).

C Larger sizes are available; consult manufacturer for sizes and tolerances.

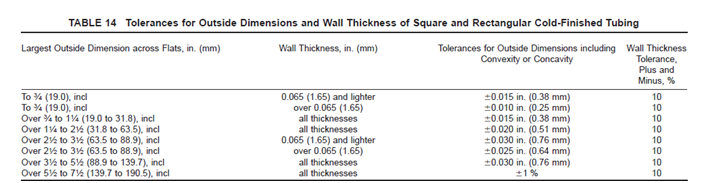

A Many tubes with inside diameter less than 50 % of outside diameter or with

wall thickness more than 25 % of outside diameter, or with wall thickness over

11⁄4 in., or weighing more than 90 lb/ft, are difficult to draw over a mandrel.

Therefore, the inside diameter can vary over or under by an amount equal to 10

% of the wall thickness.

See also Footnote B.

B For those tubes with inside diameter less than 1⁄2 in. (or less than 5⁄8 in.

when the wall thickness is more than 20 % of the outside diameter), which are

not commonly drawn over a mandrel, Footnote A is not applicable. Therefore, for

those tubes, the inside diameter is governed by the outside diameter tolerance

shown in this table and the wall thickness tolerances shown in Table Number 9.

C Tubing having a wall thickness less than 3 % of the outside diameter cannot

be straightened properly without a certain amount of distortion. Consequently

such tubes, while having an average outside diameter and inside diameter within

the tolerances shown in this table, require an ovality tolerance of 1⁄2 % over

and under nominal outside diameter, this being in addition to the tolerances

indicated in this table.

D 1 in. = 25.4 mm.

A Many tubes with inside diameter less than 50 % of outside diameter or with

wall thickness more than 25 % of outside diameter, or with wall thickness over

11⁄4 in., or

weighing more than 90 lb/ft, are difficult to draw over a mandrel. Therefore,

the inside diameter can vary over or under by an amount equal to 10 % of the

wall thickness.

See also Footnote B.

B For those tubes with inside diameter less than 1⁄2 in. (or less than 5⁄8 in.

when the wall thickness is more than 20 % of the outside diameter), which are

not commonly drawn over a mandrel, Footnote A is not applicable. Therefore, for

those tubes, the inside diameter is governed by the outside diameter tolerance

shown in this table and the wall thickness tolerances shown in Table Number

9.

C Tubing having a wall thickness less than 3 % of the outside diameter cannot

be straightened properly without a certain amount of distortion. Consequently

such tubes, while having an average outside diameter and inside diameter within

the tolerances shown in this table, require an ovality tolerance of 1⁄2 % over

and under nominal outside diameter, this being in addition to the tolerances

indicated in this table.

D 1 in. = 25.4 mm.

SUNRISE is well-known as one of the leading astma519 seamless alloy steel mechanical tubing manufacturers and suppliers in China for its quality products and excellent service. We warmly welcome you to buy the quality and durable steel products from our factory.