1. Scope 1.1 This specification covers grades of hot-formed welded and seamless high-strength low-alloy square, rectangular, round, or special shape structural tubing for welded, riveted, or bolted construction of bridges and buildings and for general structural purposes. When the steel is used...

Online Inquiry

1. Scope

1.1 This specification covers grades of hot-formed welded and seamless

high-strength low-alloy square, rectangular, round, or special shape

structural tubing for welded, riveted, or bolted construction of bridges and

buildings and for general structural purposes. When the steel is used in

welded construction, the welding procedure shall be suitable for the steel

and the intended service.

1.2 Grade II has atmospheric corrosion resistance equivalent to that of

carbon steel with copper (0.20 minimum Cu) Grades Ia and Ib have

atmospheric corrosion resistance substantially better than that of Grade II

(Note 1). When properly exposed to the atmosphere, Grades Ia and Ib can be

used bare (unpainted) for many applications. When enhanced corrosion

resistance is desired, Grade III, copper limits may be specified.

NOTE 1—For methods of estimating the atmospheric corrosion resistance of

low alloy steels see Guide G 101 or actual data.

1.3 The values stated in inch-pound units are to be regarded as the

standard.

2. Referenced Documents

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing of Steel

Products2

A 700 Practices for Packaging, Marking, and Loading Methods for Steel

Products for Domestic Shipment3

A 751 Test Methods, Practices, and Terminology for Chemical Analysis of

Steel Products2

G 101 Guide for Estimating the Atmospheric Corrosion Resistance of

Low-Alloy Steels4

3. Ordering Information

3.1 Orders for material under this specification should include the

following as required to describe the material adequately:

3.1.1 Quantity (feet or number of lengths),

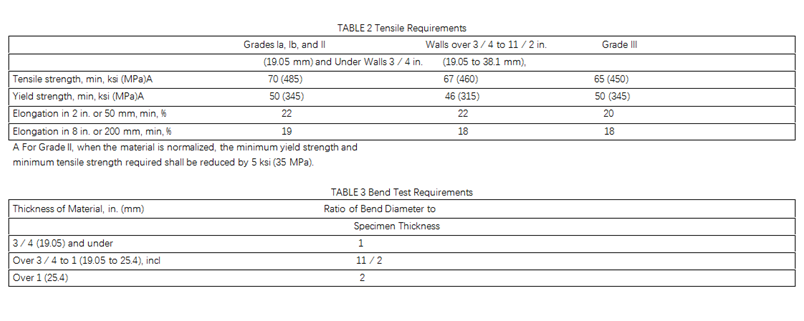

3.1.2 Grade (Table 1 and Table 2),

3.1.3 Material (round, square, or rectangular tubing),

3.1.4 Method of manufacture (seamless, buttwelded, or hot-stretch-reduced

electric-resistance welded),

3.1.5 Size (outside diameter and nominal wall thickness for round tubing

and the outside dimensions and calculated nominal wall thickness for

square and rectangular tubing),

3.1.6 Length (specific or random, see 8.2),

3.1.7 End condition (see 9.2),

3.1.8 Burr removal (see 9.2),

3.1.9 Certification (see 12.1),

3.1.10 Specification designation,

3.1.11 End use, and

3.1.12 Special requirements.

4. Process

4.1 The steel shall be made by one or more of the following processes:

open-hearth, basic-oxygen, or electric-furnace.

4.2 Steel may be cast in ingots or may be strand cast. When steels of

different grades are sequentially strand cast, identification of the

resultant transition material is required. The

producer shall remove the transition material by any established procedure

that positively separates the grades.

5. Manufacture

5.1 The tubing shall be made by the seamless,

furnacebuttwelded (continuous-welded), or

hot-stretch-reduced electric-resistance-welded process.