1. Scope* 1.1 This specification2 covers several grades of minimumwall-thickness, seamless and welded, carbon and alloy-steel tubes intended for use at low temperatures. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse affect on...

Online Inquiry

1. Scope*

1.1 This specification2 covers several grades of minimumwall-thickness,

seamless and welded, carbon and alloy-steel tubes intended for use at low

temperatures. Some product sizes may not be available under this specification

because heavier wall thicknesses have an adverse affect on low-temperature

impact properties.

1.2 Supplementary Requirement S1 of an optional nature is provided. This

shall apply only when specified by the purchaser.

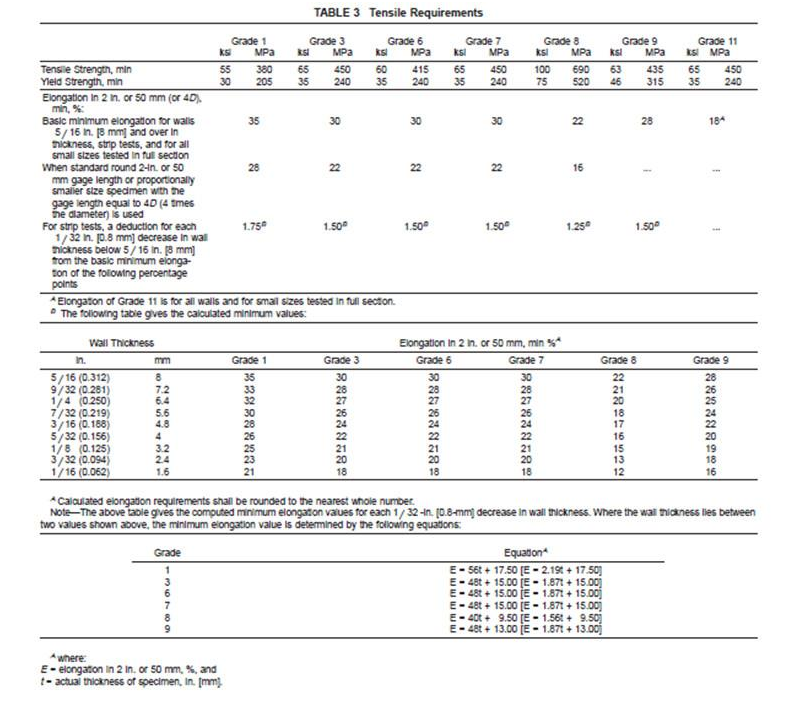

NOTE 1—For tubing smaller than 1 / 2 in. [12.7 mm] in outside diameter,

the elongation values given for strip specimens in Table 1 shall apply.

Mechanical property requirements do not apply to tubing smaller than 1 / 8

in. [3.2 mm] in outside diameter and with a wall thickness under 0.015 in.

[0.4 mm].

1.3 The values stated in either inch-pound units or SI units are to be

regarded separately as standard. Within the text, the SI units are shown

in brackets. The values stated in each system are not exact equivalents;

therefore, each system must be used independently of the other. Combining

values from the two systems may result in nonconformance with the

specification. The inch-pound units shall apply unless the “M”designation

of this specification is specified in the order.

2. Referenced Documents

2.1 ASTM Standards: 3

A 370 Test Methods and Definitions for Mechanical Testing of Steel

Products

A 1016/A 1016M Specification for General Requirements for Ferritic Alloy

Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

E 23 Test Methods for Notched Bar Impact Testing of Metallic

Materials

3. Ordering Information

3.1 Orders for material under this specification should include the

following, as required to describe the desired material adequately:

3.1.1 Quantity (feet, metres, or number of lengths),

3.1.2 Name of material (seamless or welded tubes),

3.1.3 Grade (Table 1),

3.1.4 Size (outside diameter and minimum wall thickness),

3.1.5 Length (specific or random),

3.1.6 Optional requirements (other temperatures, Section 14; hydrostatic or

electric test, Section 16),

3.1.7 Test report required, (Certification Section of Specification

A 1016/A 1016M),

3.1.8 Specification designation, and

3.1.9 Special requirements and any supplementary

requirements selected.

4. General Requirements

4.1 Material furnished under this specification shall conform to the

applicable requirements of the current edition of Specification A 1016/A

1016M, unless otherwise provided herein.

5. Materials and Manufacture

5.1 The tubes shall be made by the seamless or automatic welding process

with no addition of filler metal in the welding operation.

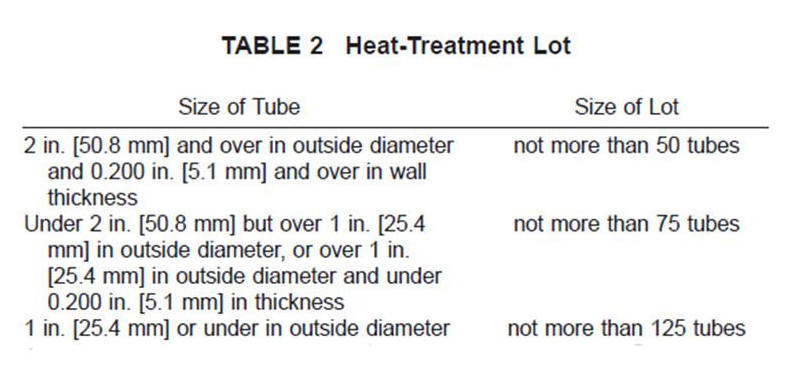

6. Heat Treatment

6.1 All seamless and welded tubes, other than Grades 8 and 11, shall be

treated to control their microstructure in accordance

6.1.1 Normalize by heating to a uniform temperature of not less than 1550

°F [845 °C] and cool in air or in the cooling chamber of an atmosphere

controlled furnace.

6.1.2 Normalize as in 10.1.1, and, at the discretion of the manufacturer,

reheat to a suitable tempering temperature.

6.1.3 For the seamless process only, reheat and control hot working and

the temperature of the hot-finishing operation to a finishing temperature

range from 1550 to 1750 °F [845 to 955°C] and cool in a controlled atmosphere

furnace from an initial temperature of not less than 1550 °F [845

°C].

6.1.4 Treat as in 6.1.3 and, at the discretion of the manufacturer, reheat

to a suitable tempering temperature.

6.2 Grade 8 tubes shall be heat treated by the manufacturer by either of

the following methods.

6.2.1 Quenched and Tempered—Heat to a uniform temperature of 1475 6 25 °F

[800 6 15 °C]; hold at this temperature for a minimum time in the ratio of 1

h/in. [2 min/mm] of thickness, but in no case less than 15 min; quench

by immersion in circulating water. Reheat until the pipe attains

a uniform temperature within the range from 1050 to 1125 °F [565 to 605

°C]; hold at this temperature for a minimum time in the ratio of 1 h/in.

[2 min/mm] of thickness, but in no case less than 15 min; cool in air or

water quench at a rate no less than 300 °F [165 °C]/h.

6.2.2 Double Normalized and Tempered— Heat to a uniform temperature of

1650 6 25 °F [900 6 15 °C]; hold at this temperature for a minimum time in

the ratio of 1 h/in. [2min/mm] of thickness, but in no case less than 15 min;

cool in air. Reheat until the pipe attains a uniform temperature of 1450 6

25 °F [790 6 15 °C]; hold at this temperature for a minimum time in the

ratio of 1 h/in. [2 min/mm] of thickness,but in no case less than 15 min; cool

in air. Reheat to a uniform temperature within the range from 1050 to 1125

°F [565 to 605°C]; hold at this temperature for a minimum time of 1 h/in.

[2min/mm] of thickness but in no case less than 15 min; cool in air or

water quench at a rate not less than 300 °F [165 °C]/h.

6.3 Material from which impact specimens are obtained shall be in the same

condition of heat treatment as the finished tubes.

6.4 Whether to anneal Grade 11 tubes is per agreement between purchaser

and supplier. When Grade 11 tubes are annealed they shall be normalized in

the range of 1400 to 1600°F [760 to 870 °C].

SUNRISE is well-known as one of the leading astma334 seamless and welded alloy steel tubes for low temperature service manufacturers and suppliers in China for its quality products and excellent service. We warmly welcome you to buy the quality and durable steel products from our factory.