1. Scope 1.1 This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products intended for low and moderate temperatures and corrosive service where heat treatment is not necessary for corrosion resistance. Table 1 lists the five grades...

Online Inquiry1. Scope

1.1 This specification covers straight seam and spiral butt seam welded

unannealed austenitic stainless steel tubular products intended for low

and moderate temperatures and corrosive service where heat treatment is not

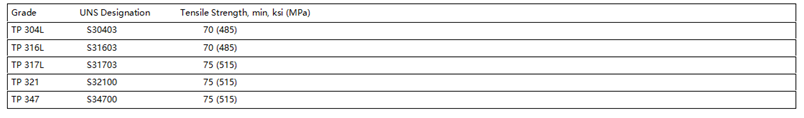

necessary for corrosion resistance. Table 1 lists the five grades covered

by this specification. The user of this specification should be aware that

a minimum amount of testing and examination is required of the basic

product. The user requiring additional testing or examination is referred

to the supplemental requirements or Ordering Information, or both. Users

requiring a tubular product with post-weld heat treatment or with

radiographic examination are referred to Specification A 312/

A 312M, A 358/A 358M, or A 409/A 409M, as applicable.

1.2 This specification covers welded unannealed tubular products 3 in. (75

mm) through 48 in. (1200 mm) in outside diameter and in nominal wall

thicknesses of 0.062 in. (1.5 mm) through 0.500 in. (12.5 mm) produced to this

specification. Tubular products having other diameters or wall thickness,

or both, may be furnished provided it complies with all other requirements

of this specification.

1.3 The values stated in inch-pound units are to be regarded as the

standard.

2. Referenced Documents

2.1 ASTM Standards:

A 240 Specification for Heat-Resisting Chromium and Chromium-Nickel

Stainless Steel Plate, Sheet, and Strip for Pressure Vessels2

A 262 Practices for Detecting Susceptibility to Intergranular Attack in

Austenitic Stainless Steels2

A 312/A 312M Specification for Seamless and Welded Austenitic Stainless

Steel Pipes3

A 358/A 358M Specification for Electric-Fusion-Welded Austenitic

Chromium-Nickel Alloy Steel Pipe for High- Temperature Service3

A 370 Test Methods and Definitions for Mechanical Testing of Steel

Products2

A 409/A 409M Specification for Welded Large Diameter Austenitic Steel Pipe

for Corrosive or High-Temperature Service3

A 700 Practices for Packaging, Marking, and Loading Methods for Steel

Products for Domestic Shipment4

A 941 Terminology Relating to Steel, Related Alloys,

and Ferroalloys3

A 999/A 999M Specification for General Requirements for Alloy and Stainless

Steel Pipe3

E 340 Test Method for Macro etching Metals and Alloys5

E 527 Practice for Numbering Metals and Alloys (UNS)3

2.2 AWS Standards:

A 5.4 Corrosion—Resisting Chromium and Chromium-Nickel Steel Covered Welding

Electrodes6

A 5.9 Corrosion–Resisting Chromium and Chromium-Nickel Steel Welding Rods and

Bare Electrodes6

2.3 SAE Standard:

SAE J1086 Practice for Numbering Metals and Alloys(UNS)7

3. Terminology

3.1 Definitions:

3.2 The definitions in Specification A 999/A 999M and Terminology A 941

are applicable to this specification.

4. Ordering Information

4.1 Orders for material to this specification should include the

following:

4.1.1 Quantity (feet, meters, or number of pieces),

4.1.2 Name of material (welded unannealed austenitic stainless steel

tubular products),

4.1.3 Straight seam or spiral butt seam,

4.1.4 Grade (see Table 1),

4.1.5 Size (outside diameter and specified wall thickness)(see 10.3 and

10.4),

4.1.6 Length (mill standard lengths, or specify cut lengths)(see 10.1),

4.1.7 Optional requirements (Supplementary RequirementsS1 to S5),

4.1.8 Certification requirements,

4.1.9 Specification designation, and

4.1.10 Special requirements.

6. Manufacture

6.1 The tubular products shall be made from flat-rolled steel sheet, coil,

or plate by a shielded arc-welding process. The material used for

manufacture shall conform to the requirements of one of the grades of

Specification A 240 listed in Table 1. At the manufacturer's option,

filler metal may be used.

6.2 Tubular products 14 in. (350 mm) in diameter and smaller shall have a

single longitudinal weld or a spiral butt weld seam. Tubular products of

larger diameter may have a maximum of three longitudinal welds. All weld tests,

examinations, inspections, or treatments are to be performed on each weld

seam.

6.3 Circumferentially welded joints of the same quality as the

longitudinal or spiral joints shall be permitted by agreement between the

manufacturer and the purchaser.

6.4 All tubular products shall be furnished clean and free of scale.

6.5 Welding:

6.5.1 The welds shall be made by the manual or automatic electric-welding

process.

6.5.2 The welded joints may show a reinforcing bead no greater than 1⁄16

in. (1.6 mm) on either surface of the tubular product. At no place shall

the thickness of the weld section be less than the minimum wall thickness

permitted by the tolerances of 10.4. The weld bead may be removed at the

option of the manufacturer or upon agreement between the

manufacturer and purchaser.

6.5.3 Injurious weld defects shall be repaired by removal to sound metal

and rewelding.

6.5.4 The alloy content (chromium, nickel, molybdenum, columbium, and carbon)

of the filler metal shall conform to that required for the plate or the welding

electrodes as shown in Table II of Specification AWS A5.4 or in Table I

of Specification AWS A5.9, except that when welding on Type 321 base

metal, the deposited weld metal may correspond to Type 347.

7. Mechanical Test Requirements

7.1 Each lot shall be subjected to one transverse tension test and two

transverse guided bend tests.

NOTE 1—The term lot applies

to all pipe of the same grade, of the same thickness, produced from the

same heat with the same weld procedure.

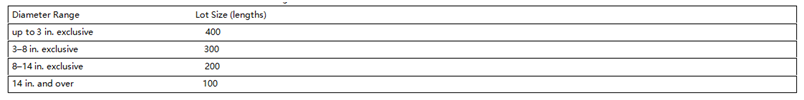

7.2 The maximum lot size shall be in accordance with the following

table:

Tensile Requirements

Chemical Requirements

A New designation established in accordance with Practice E 527 and SAE J1086,

Practice for Numbering Metals and Alloys (UNS).

B The carbon analysis shall be reported to the nearest 0.01 %, except for the

low carbon (0.030) types, which shall be reported to the nearest 0.001 %.

C The titanium content shall be not less than five times the carbon content and

not more than 0.70 %.

D The columbium plus tantalum content shall be not less than ten times the

carbon content and not more than 1.10 %.

SUNRISE is well-known as one of the leading astm a778 welded unannealed austenitic stainless steel tubular manufacturers and suppliers in China for its quality products and excellent service. We warmly welcome you to buy the quality and durable steel products from our factory.